Failure Analysis & Problem-solving

our service

Failure Analysis & Problem-solving

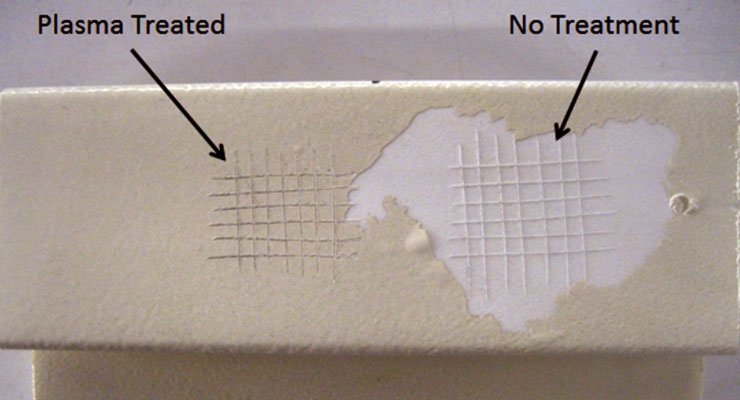

In cases of coating failure, Sparkle Coating Consultants are called upon to assess the situation and determine the root cause of the coating failure through our reversible failure analysis method, which includes practical solution, laboratory testing and guided resolution.

Surface preparation, coating application procedure, and materials selection are all considered in this comprehensive assessment of coating failure. Our experienced team of NACE Coating inspectors will be able to tell you precisely where the problem is, what went wrong, and what to do about it.

A site visit will often include taking samples of the coatings and base surface for laboratory testing, microscopic examination of the thickness and cohesive integrity of the coatings, assessment of any cleaning or maintenance performed post-application, and environmental factors affecting the surrounding area.

Our consulting team welcomes any questions on coatings or surface finishing processes for Ferrous, non-ferrous, and other materials. And finally, all our findings and recommendations are documented in a detailed, full report with photographs included.

Our Service

Process Handling

In cases of coating failure, Sparkle Coating Consultants are called upon to assess the situation and determine

the root cause of the below problems through our reversible analysis method.

Initial Consultation and problem assessment

Inspection, Sample Collection & Data Collection

Problem identification

Laboratory testing and Failure analysis

Root Cause identification

Corrective action & Troubleshooting

Verification of corrective

action